What is a car filler?

The filler is a paint included in the refinish process within the category of base or preparation paints (along with putties and primers), as it’s the last coat to be applied before the finishing paint.

Filler paint is of utmost importance in the repair process, directly influencing the work productivity and profitability and the final quality of the finish.

Fillers help in levelling repaired areas superficially, hiding some superficial defects such as sanding marks and small irregularities.

However, it is not advisable to use filler paint to fill big defects. Excessive product loading on the surface could eventually lead to painting imperfections such as lower brightness, air bubbles or cracks. To carry out this filling, the professional already relies on the polyester putties which must be applied prior to filler paint.

Features of the bodywork filler paint

Insulation and support

One of the main tasks of the filler is its provide support and insulation between previously prepared surfaces (putty layers, metal, cataphoresis, etc.) and the finishing paint.

Antirusting protection

Providing antirusting protection to the metal, helping to prevent potential rusting defects on the bodywork. Some primers have anti-corrosion components, which enable and improve the metal’s protection.

Improving colour matching (base shade matching)

The colour of the filler has a direct influence on the matching of the finish colour.

It is advisable to always consider the shade of the filler to be used according to the colour of the finish paint.

This process will help improve colour matching while at the same time obtaining greater coverage power. This will avoid having to apply more finishing coats than what is recommended by the manufacturer, thus improving the time and cost effectiveness of the repair.

To make it easier to match and choose the priming colour, you should rely on thegrey-scale system.

It is a system composed of 3 colours (white, grey and black), which combined with each other can give rise to different shades of grey, depending on the shade of the finishing colour.

When you use a grey colour with similar shade (light-dark) to that of the finishing colour, you will obtain better results in terms of colorimetry and coverage.

Thus, for white and light colours you should use light-coloured fillers, and for darker colours you should use dark shades of filler paint, depending on the shade of the finish colour.

As in the BESA colour management software, the base colour is proposed by the program itself to facilitate choosing and obtaining optimal colour matching.

Providing smoothness to the surface

Another feature of priming is to make the surface more uniform, levelling out small irregularities such as sanding marks and small pores enhancing the finish paint’s aesthetics and good appearance.

Types of car filler

Filler paint can be classified into two groups: based on its sanding, or based on its specific features during the repair:

Types of filler according to the sanding

► Sandable filler

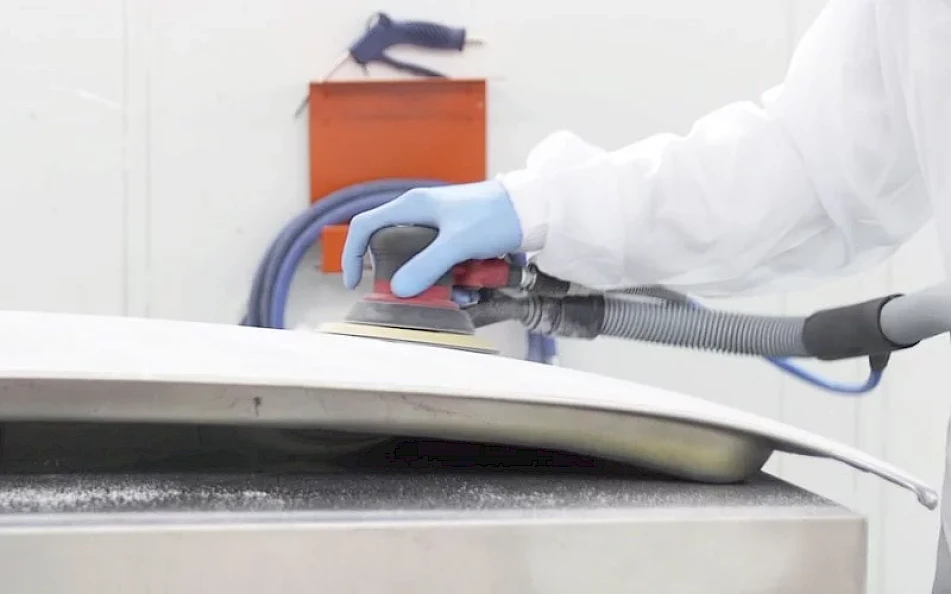

Sandable fillers are those that once applied and dried, must be sanded.

Sanding will enable spreading well the paint and anchoring the final coat.

These are priming that show an excellent drying and sanding performance.

This type of product and its repair process are the most widespread in bodyshops. Some examples of this type of filler are the BESA-CAR or BESA-EXPRESS.These products stand out for their great covering power and easy sanding.

► Wet-on-wet fillers (W/W)

These fillers provide the necessary anchorage and insulation coat between the primer and the finish paint and requires no sanding process.

After complying with the manufacturer’s drying time, the finishing paint can be applied directly to the filler, when it is still humid (over wet).

The use of the wet-on-wet processes can have a significant influence on the time spent and the productivity of the repair. It is used for priming new parts with cataphoresis or in interior painting of parts such as bonnets or doors.

An example of this category would be the BESA-WET, an easy-to-apply filler that allows you to paint after 15 minutes.

Priming according to specific characteristics in the repair

High-build fillers

This type of filler provides excellent coat thickness, which results in uniform, even and easily sanded surfaces. They are often used to repair larger surfaces and offer good adhesion on different substrates. Fillers that can be included in this category: BESA-CAR and URKI-FILLER.

High solids content fillers

This filler category has excellent balance between fast drying, good sanding and high coat thickness thanks to its high solid content.

Because of their versatility and performance, they are the most widely used types of filler in bodyshops. Again, in this category we can highlight the priming paint BESA-CAR and BESA-EXPRESS.

Fast fillers

This type of filler can be used for spot repairs since they allow shortening the time between application and sanding.

They usually harden at a higher speed, being able to sand them earlier and thus increasing productivity at the workshop. A good example could be BESA-EXPRESS, which is also highly versatile and can be applied to both metal and plastic substrates: PVC, PC, PS, SMC, PET and NORYL.

Primer-filler

They provide anchoring and rustproofing protection to metal, in addition to good uniformity, preventing the appearance of contraction, pores or sandpaper marks. BESA primer-paint is in this category.

Spray fillers

They are mainly used in minor repairs, optimising the time spent in preparing and application of the process, or as a cover for bare surfaces after sanding the filler.

They are usually quick-drying fillers. Sprayed in thin coats they allow repainting without prior sanding. With higher coats, we recommend sanding with abrasive disk P-400/P-500 or higher, after 2-4 h. For example: URKI-FILLER spray-on.

Conclusion

The use and choice of the appropriate filler depending on the type of repair to do will be crucial in the final finish.

As professionals, we must understand in depth the different types that exist, their behaviour and the particularities of each in order to optimise the priming process in the repair.