What is two-component paint or 2K paint

Some of the paints used in bodywork, such as filler paint or clear coat, are 2-componentpaints.

This means that these paints must be mixed with a hardener for them to work properly.

The base and hardener mixture accelerates the paint’s drying process.

This mixture of products (base and hardener) triggers a polymerisation process, resulting in rapid drying or solidification of the paint.2-component paints offer a number of advantages over 1K or single-component paints:

- Greater brightness and more lasting.

- Greater hardness and resistance both chemically (oils, fuels, etc.) and mechanically.

- Better adhesion to the part and resistance to yellowing.

- More elasticity and washability.

2K paint components

Component A (paint or clear coat)

This component defines the type and characteristics of the finish paint. There are many types, such as filler paint or clear coat.

Component B (catalyst or hardener)

It is the element that causes the hardening chemical reaction without which the paint (or component A) would not dry.

Component C (thinner)

Some applications will also require the use of a third component such as a thinner.

Thinner will allow adapting to the painting conditions and type of application

This product allows to change the viscosity of the mixture, adapting the application to the painting conditions and type of application, in order to ensure optimal paint extensibility, coverage and behaviour.

Methods for mixing two-component paint

During the mixing process, different tools and utensils will help you achieve a correct mixing ratio:

Paint mixing with precision weighing scale (recommended)

The precision weighing scale is undoubtedly the most practical and efficient method for obtaining an accurate mixing ratio of the different components. This, combined with an advanced colour management software as the one used in the URKIMIX-PRO two-coat system, enables colour adjustment in a simple and intuitive way, while reducing the time used in the paint mixture preparation process.

The data displayed on the scale is based on weight and not volume

For an accurate mixture of 2K paint, simply follow the colour indications, ensuring that the correct amount of each component is added. This can be checked on the precision weighing scale’s display.

Finally, stir the product regularly to obtain a uniform mixture.

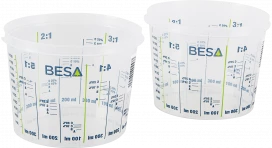

Mixing paint with mixing containers

The mixing container is another method that allows to easily calculate mixture rations, following the rules printed on the container for each component.BESA has mixing containers for different mixing ratio of component A and component B (1:1, 2:1, 3:1, 4:1, etc.) ratios. There are different size or capacity containers depending on the amount of product you want to apply.

Inside the mixing containers there is a fast paint preparation system, called FPP (Fast Paint Preparation). This system includes a regulated container and a flexible single-use container, which reduces the paint preparation time, and suppresses the cleaning process of the container.

The FPP system helps to reduce the paint preparation time, and suppresses the cleaning process of the container.

It is an easy, quick and clean solution to apply paint (both water and solvent based), and it is adaptable to all types of paints.

Mixtures with volume rules

As in the case of mixing containers, you must know beforehand the mixing ratio to be made (packaging or technical data sheet).

This is the least recommended method among those mentioned, and may result in greater inaccuracies in the paint mixture.

There are rules with different mixing ratios (2:1, 3:1, etc.). Volume rules require using a non-conical vertical container or recipient to obtain an accurate ratio of paint or clear coat, hardener and thinner. The size of the container should be taken into account for a correct mixing ratio.

Example of 2K paint mixing with mixing containers: steps

To illustrate the example of a two-component paint mixture, we will use filler paint as component A, and the amount to prepare will be 300 ml.

Check the manufacturer’s technical data sheet for indications on the product’s mixing ratio. In this case, 4:1:10%.

This means that you must pour 4 parts of paint for each part of hardener, including 10% of thinner of the total mixture (paint + hardener).

1. Safety and pre-protection

To make this mixture with full guarantee, it is essential that both the bodywork and paint shop and the professional follow all the safety regulations provided for chemical product handling.

The mixing area and the product storage area must be clean and tidy, with appropriate ventilation and without elements that hinder product and tool handling.

In addition, it is important to make sure that there are no contaminants that could alter the composition of the mixture to apply, and that all utensils (containers, recipients, etc.) and tools to be used are clean and in good condition.

As for the professional painter’s equipment, PPE will be required such as coveralls, latex gloves, protective goggles or FP2 certification face mask or higher.

BESA has a wide range of personal protection equipment aimed at ensuring the professional painter’s integrity and protection.

Following the instructions provided in the technical data sheet

As noted above, different components are required to obtain the correct mixing ratio.

This proportion (defined by volume) is indicated in the product data sheet and on the product packaging (pictograms).

Following these indications will be essential to obtain an optimal result in the application.

Each paint manufacturer provides information on the mixing ratio for correct hardening and behaviour of their product.

It should be noted that the amounts and type of each component to be used may vary depending on different factors such as room temperature, type of finish, etc.

Once you have decided on the amount of product to be mixed, add the different components according to the mixing ratio indicated by the manufacturer.

Always follow the mixing ratios and do so in the following order:

1- Component A (paint / clear coat).

2- Component B (hardener).

3- Component C (thinner).

3. Include filler paint or component A

Pour component A, adjusting the amount to the rule printed on it. In this case, 240 ml.

4. Include hardener or component B

Pour component B, the hardener. For a 4:1 mixing ratio, you should pour 60 ml. Stir the mixture with a stick until a regular and uniform mixture is obtained.

5. Add the dilution

Pour 10% of the total mixture (base + hardener): 30 ml. Stir the mixture again. If you are not using a single-use application system, use a paper filter to remove any impurities in the mixture.

Follow these steps to achieve an accurate paint mix, while optimising product consumption in the workshop.