A training platform in continuous innovation that will help you to improve your knowledge and work processes.

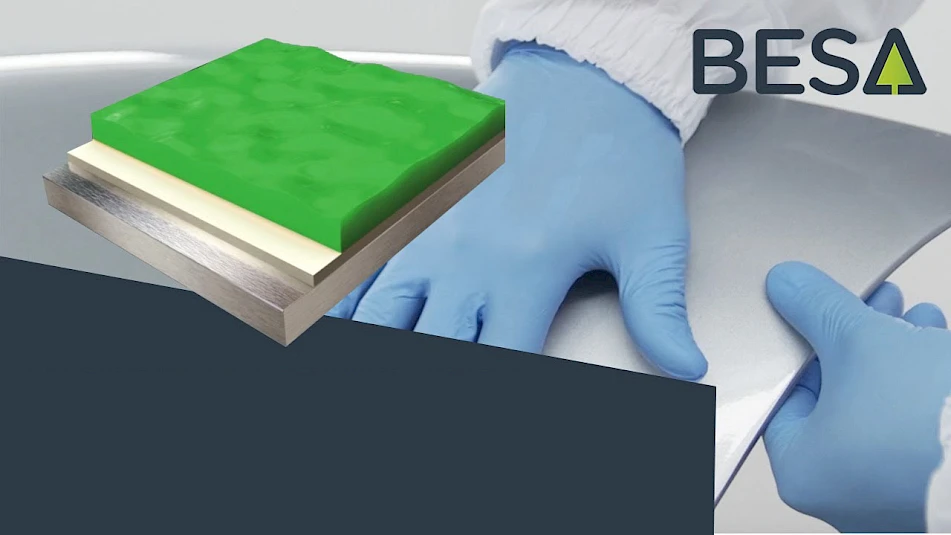

PAINT DEFECTS

Solution for the main paint application defects.

CATEGORIES

Face-to-face training courses

In constant search for excellence

We have a fully-equipped Training Centre, where we conduct courses for our staff, and for retailers and customers, focusing on specific products/services and designed in response to their needs.